|

In the introductory article, I showed how to set up Gus Smalley's Beginner

Boost V. 2 with tone stack on a solderless breadboard. Now we will commit to a soldered build on perfboard

and house the effect in a gig-worthy enclosure. If you bought one of the breadboarding kits, the parts can be re-used

if you wish. The result will be a professionally-useful pedal with all of the

features that you would expect of a commercially-manufactured "boutique" design.

As I have done with some of my other "Breadboard-To-Box" projects, I will

describe some of the electronic and mechanical considerations that went into

developing the finished design. If you are new to building pedals, you'll

learn some good construction habits and patterns of thinking and planning that

will be helpful in building more complex designs.

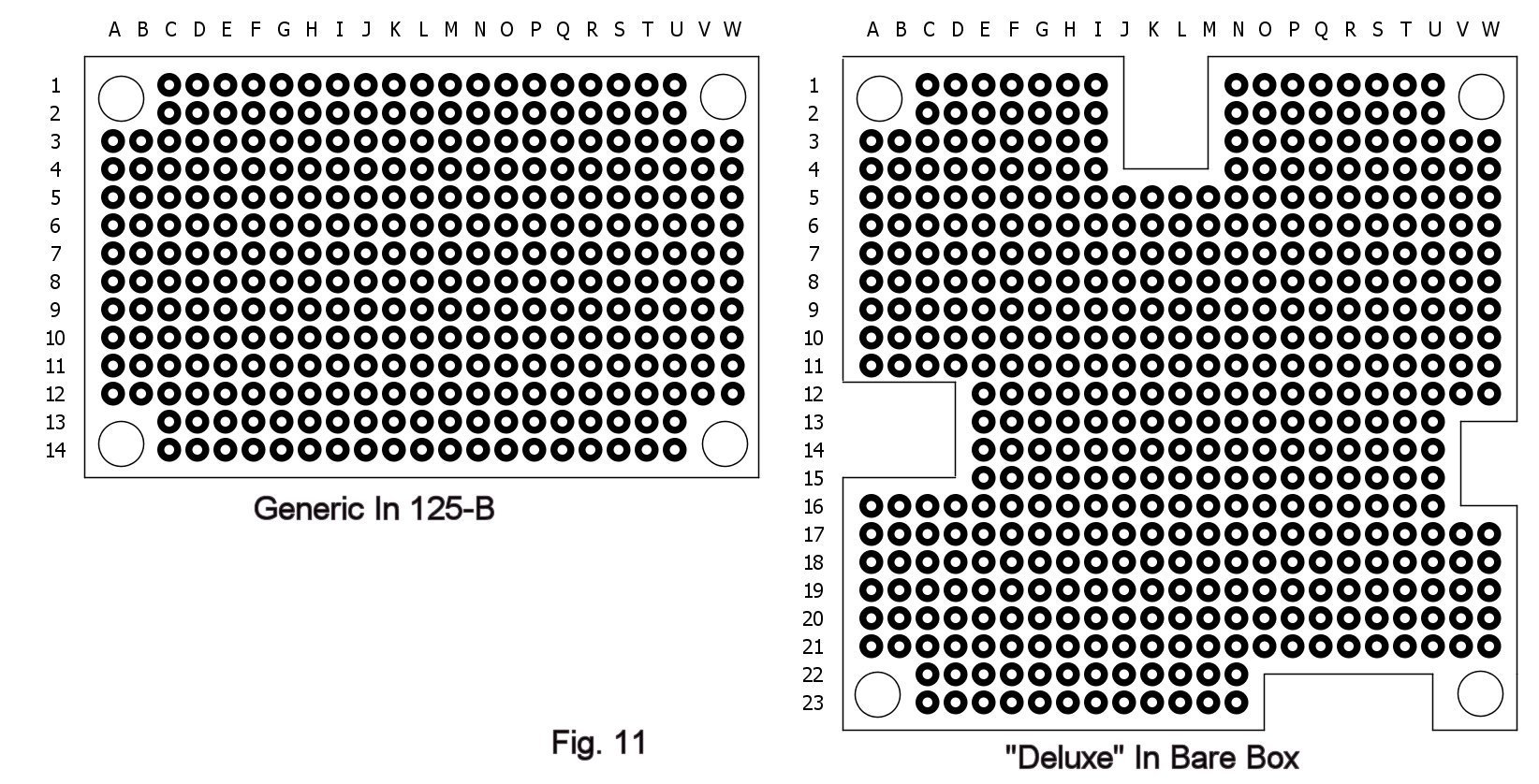

I'll show two possible builds: The generic build on the right uses a

standard 125-B enclosure that is available from many sources. On the left

is a "deluxe" build in the made-for-Small Bear Bare Box #1. That one uses a

number of made-to-order parts and specific modular connectors to produce a

result that is comparable to a manufactured product. The sloped design

reduces greatly the risk of stomped pots, and it includes a battery door.

The difficulty levels of both builds are about the same, and complete

kits are available to take you either way. |

|

|

|

|

|

|

Breadboard To Box - What Is Involved?

If you followed the breadboard build to its end, you have a working circuit, complete from input to output, like

Figure 1.

Clearly, a number of elements need to be added to make this into

a buildable design for a finished pedal. The most important is bypass switching, to allow the effect to

be foot-switched in and out. There are numerous schemes for doing this, and I

chose one that's known to work well and uses components that can be found almost

anywhere.

|

|

|

|

3PDT True-Bypass Switching With In-Use LED Driver - How It

Works

Here's a bottom view of a typical 3PDT (Three-pole,

Double-throw) footswitch. It has nine contacts, and they work as shown in the schem

in Figure 2. Push/release once and the moving contacts (2, 5 and 8) connect to #3, #6

and #9. Push/release again

and they go back. We call this a "latching" or "alternate-action" switch,

because the contacts remain in their new positions when you release the switch.

|

|

|

|

Let's add this to the schematic, trace through the connections and see how

the switching works in practice. In Figure 3, the effect is

bypassed. The guitar input goes from the moving contact, pin 2, through

stationary contacts pin 1 and pin 4 (which are connected with a jumper) to

moving contact pin 5 and then to the output jack When the switch is stomped,

the input jack sees the effect input through pin 3, and the output jack sees

the tone

control through pin 6. Two contacts of the third pole switch the LED on and

off. OK so far? If you still have the circuit on your breadboard and want to set

up the bypass to see/hear it work, by all means do so.

Answer to a FAQ: There are other ways to wire a stomp switch,

with and without an in-use LED. They will all work, though some may be more

suitable than others in a particular design situation. If you want more

information, check the Beginner FAQ or other on-line sources.

|

|

\ \ |

|

Power - Internal and External

While we were on the breadboard, we switched power off by

disconnecting the battery. That won't work in a pedal, so we have to make some

arrangements. And there are several issues:

-

We want a DC power jack, and we want the battery to be cut off when an external power supply is plugged in.

-

We want the circuit to be protected from reverse connection of

power.

-

We want battery power to be cut off when the guitar plug is

removed from the input jack.

Most modern pedals accomplish all of this in the same ways.

External power comes in through a jack like the one of the ones in Fig. 4. These styles

are designed to be mounted on the panel of an enclosure, while others mount on

a circuit board. They all work similarly, as shown in the small schematic

(Fig. 5).

Contact #1 connects to the shell of the power plug, which will be positive in the

typical negative-ground pedal design. Contact #3 forms a normally-closed switch

with contact #1; it shorts to #1 until a power plug is inserted. Contact #2 is

the center pin, which will be ground in this configuration. |

|

|

|

Switching the battery off when the guitar is unplugged is done by using a stereo

jack for the input. Since the Ring contact of such a jack is shorted to ground

through the sleeve of a guitar plug, it provides a cheap and easy way to

implement a necessary function. Do take a look at the physical jack and work out

for yourself what is happening if you need to. Figure 5 shows the whole idea in

schematic form. Diode D1 takes care of reverse polarity protection; it will block current flow

if the battery or power supply is connected incorrectly. |

|

|

|

|

|

Here is the whole, buildable schem, including all of the support circuitry.

|

|

The "Bare Bones" Of Planning A Build |

|

|

|

When working out a design, the first job is to translate the schematic to a

suitable layout on a chassis or circuit board. You may notice that the

layouts of many "Build Your Own Pedal" articles are pretty ad-hoc and

haphazard. I organize my builds by following a rule that I worked out from

listening to some of the

engineers on the Forum, especially R. G. Keen: "Pick a suitable enclosure,

then figure out where the off-board components will go, and then lay out the

board so that the connections to the off-board components are as direct as

possible." |

|

|

|

I know that this will be a two-knob build, so I will want

terminations for:

- Two potentiometers

- DC Power

- Input from guitar

- Output to amp

- Stomp Switch

- In-Use LED

I've already chosen a rectangular enclosure, oriented vertically like a

typical off-the-shelf pedal. Putting the input jack on the right has become

an industry standard, the stomp switch logically goes at the bottom and the

power jack and pots at the top. Where the LED goes is a matter of taste; I

usually locate it on the top left side.

This defines the basic layout of the enclosure, and we can now think

about laying out the circuit board. When looking at the top of the case, the

board inside actually sits component-side down, right?. So, turning the case

over gives our first look at where the off-board terminations will be (Fig. 8). |

|

|

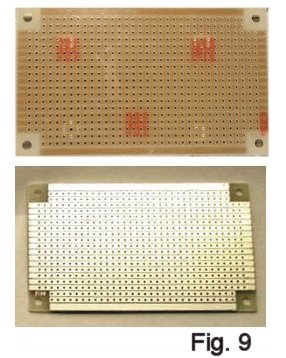

FAQ: Which Material? Pad-Per-Hole vs. Veroboard You will

see many designs laid out on stripboard, also called Veroboard, or just Vero

(Fig. 9). While I stock it because it's very popular, I don't recommend it for first

builds. It's very convenient to use, but it does not force you to follow the

logic of a schematic and wire point-to-point. To my mind, that's an

essential skill that a beginner needs to develop.

I recommend perforated

circuit board, or perfboard as it is commonly called (Fig. 10). Each hole on the

bottom of the board is surrounded by a tinned copper

pad to which solder can bond. This type of stock is called, appropriately,

pad-per-hole perfboard. Component leads are inserted through the holes and

soldered in place on the opposite side. Connections are made with short lengths

of bare wire.

|

|

|

|

Tools and Materials Some DIY builds are entirely

paint-by-number, which I don't like--they don't teach much. Both builds in this

article

include some hand tooling. Before you begin creating the board, let's make sure that you have all the tools

required. You'll need a few basics:

- 25- to 35-watt soldering iron, rosin-core solder and cleaning sponge

- Small screwdriver(s)

- Small chain-nose pliers and side-cutters

- Small locking-grip ("Vise-grip") plier

- X-acto or similar knife

- Self-locking tweezers or other "third hand"

- Small alligator clip

- Colored pencil or "Hi-liter" felt-tip marker

- Some small round and flat files

- A pointed steel "pick" or scratch awl

- De-soldering braid

If you buy one of my kits, case is pre-drilled. If you are

rolling-your-own, be prepared to borrow

a drill if you don't have one.

|

|

For finishing the case you'll need:

- 220-grit and 400- (or finer) grit carborundum paper

- Acetone, denatured alcohol

- Spray primer and enamel

- Decal stock or decals

- Clear lacquer like Krylon

These tools, and many others, are available in my Stock List.

|

|

|

|

|

|

First Job - Tool The Perfboard |

|

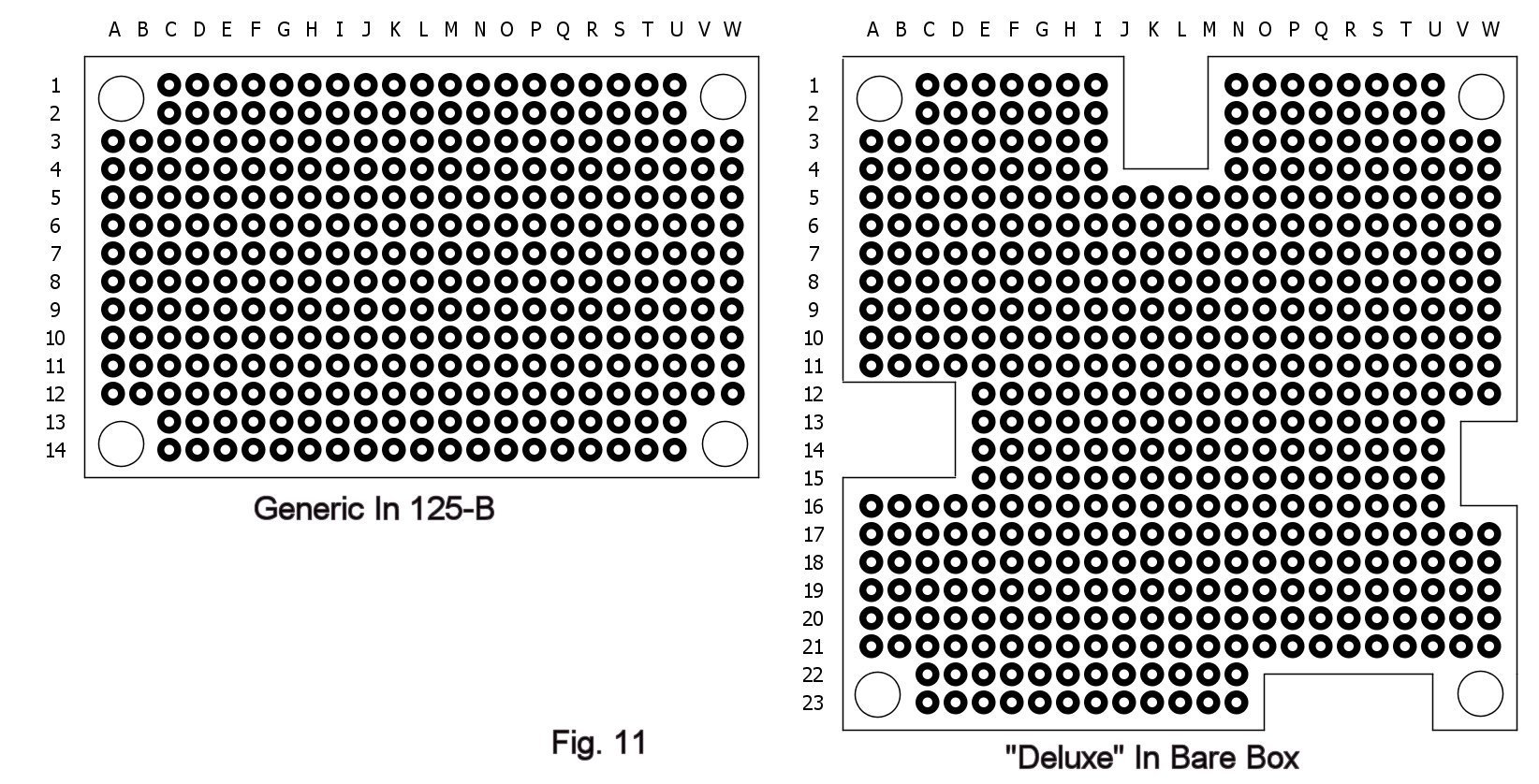

Here is how to tool the 60 x 60 board

for both the generic and the Bare Box builds. However, the methods are similar if you are using

locally purchased material of any larger size. The drawings below (Figure

11) show what we need to wind up with.

For the generic build, the 60 x 60 needs to be cut down to 14 rows and

two mounting holes must be added. If you don't have a Dremel tool, use a

knife and a steel rule to score

the board in the 15th row all the way across (Figure 12). Score a dozen or so times in

order to deepen the line. If you have a vise or have access to one, clamp

the piece in the jaws on the score line. Wedging the piece in a door frame will

also work (Figure 13). Apply steady pressure on the edge until you feel the

material snap. Borrow a drill if necessary to create two new 1/8" mounting

holes (Figure 14).

If you have a Dremel tool

and an abrasive cutoff wheel, this combination is by far the easiest way to

work perfboard. However, if you go this route, be aware that the dust that

the operation throws off contains fiberglass.

WEAR GLOVES, GOGGLES AND A

FACE MASK!

|

|

|

|

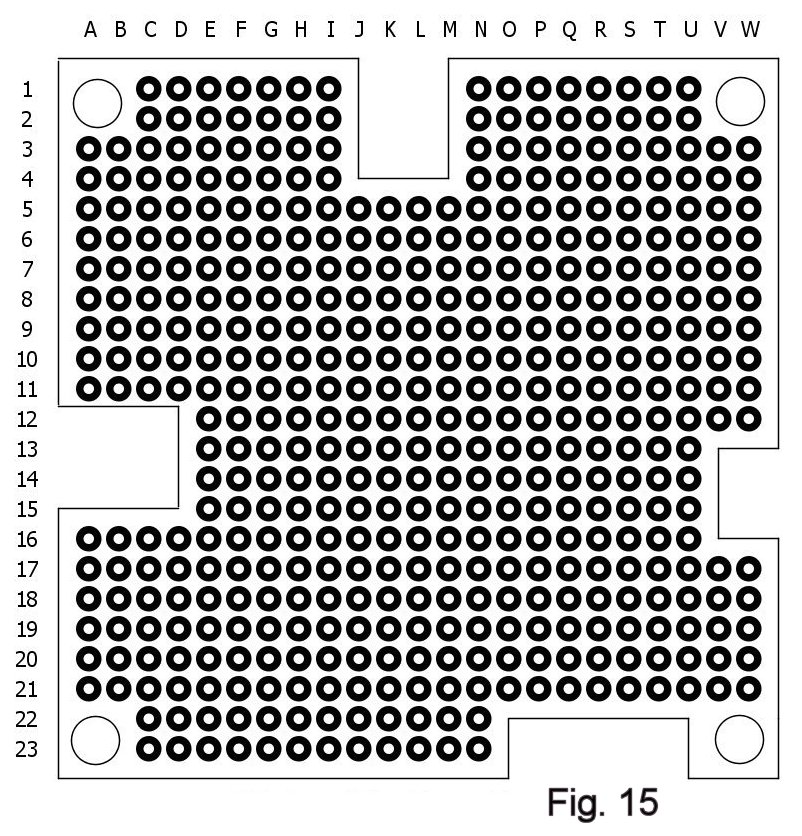

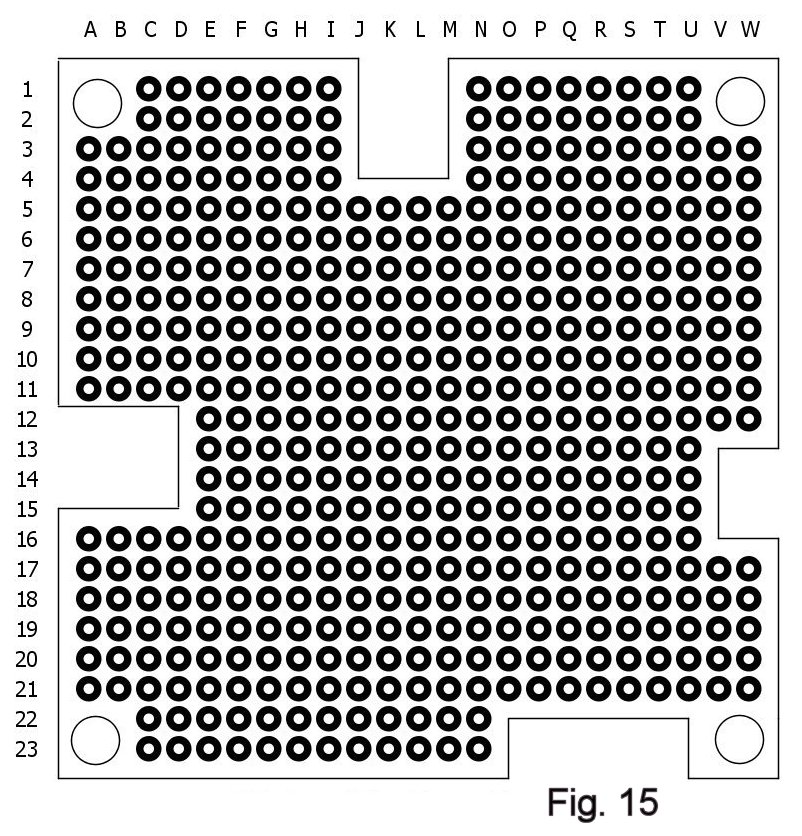

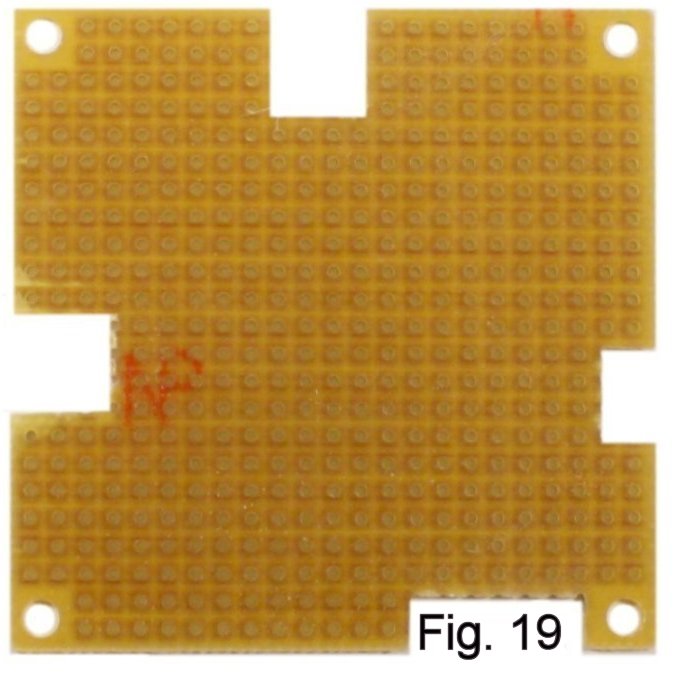

The 60 x 60 is exactly sized for the Bare Box, but it needs four cutouts to

pass wiring from the off-board components. The coordinates are shown in

figure 15. Using a knife, mark the outlines of the areas that need to be cut away (Fig. 16).

|

|

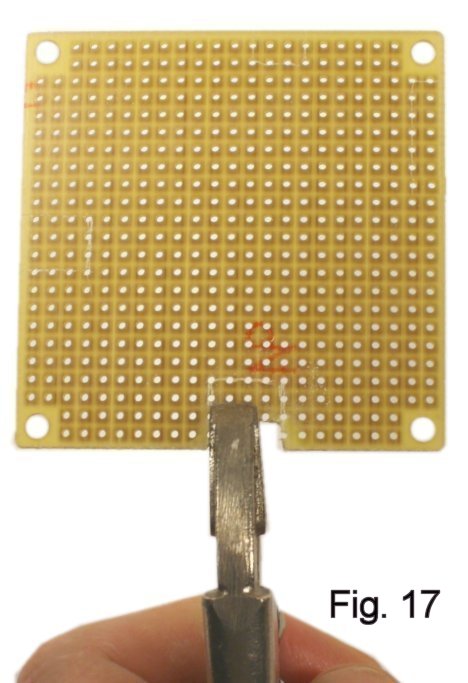

If you are limited to manual tools, continue using the knife and score each line

that you have marked a dozen times. Then use pliers to bend and snap on the

score lines, "nibbling" a little at a time (Fig. 17). Clean up the

edges with a flat file (Fig. 18) and you should wind up with a piece that looks

like figure 19.

|

|

|

|

Short Answer To An FAQ: How Do You Get To A Workable Component Layout? |

|

The long answer really needs another tutorial by someone who has designed

boards for a

living, like R. G. Keen. In

his case, he wrote a book.

Short answer: We know where the off-board connections will be, so figuring out

exactly where each component will go needs a lot of

place-and-try. I see many attempts to use pencil-and-paper for this process,

and I always advise against it; there are numerous software packages--some

free to download--that make laying out a board both a lot easier and fun. Like all

programs, they have a learning curve. But if you invest the time, you'll be

amazed at what you can do going forward. I use DIY Layout Creator, which can

be downloaded from a link on the Forum. If you are building in the Bare Box, continue in the next section. For

the generic build continue below.

|

|

|

|

|

|

Stuffing The Board For The Bare Box Below is the

board layout and a re-cap of the parts list. You are seeing the board

in "X-Ray" view; the red lines are connections that we will make with bare

wire on the bottom of the board.

Print a copy of this drawing and the schematic so that you can mark off connections with a

highlighter as you work. This is one of my time-tested methods for catching

mistakes before they cost me time and frustration.

|

| R1 |

4.7 Meg |

| R2 |

1K |

| R3 |

120K |

| R4, R5, R8, R10 |

47K |

| R6 |

10K |

| C1 |

100 mf. |

| C2, C6, C7 |

.01 mf. |

| C3 |

.47 mf. |

| C4 |

22 mf. |

| C5 |

1 mf. |

| Q1 |

2N2222A or similar |

| D1 |

1N5818 |

|

|

|

|

We are ready to populate

("stuff") the board. While components can be added in any order,

I'm going to suggest that you start by installing the Molex headers for

power, signals, switching and the pots. With those in place, you'll have good physical

reference points for installing all of the other parts. Please note that I don't

cover basic soldering techniques in this article; you may want to check a

reference and do some practicing if this is your first build.

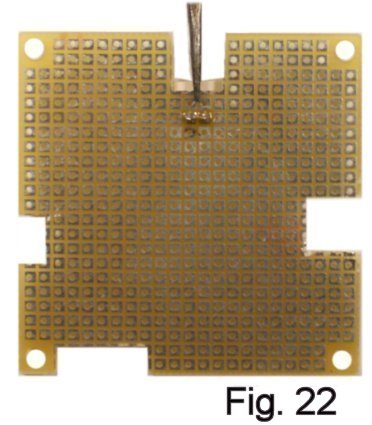

Find one of the

two-pin horizontal Molex headers (Fig. 21). Install with its pins in indexes

K-6 and L-6, use self-locking tweezers to hold it and solder in place

(Fig. 22).

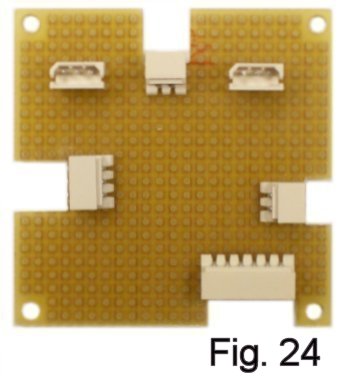

In the same way, locate, install and solder in place the other horizontal Molex

headers: three-pin for the input, two-pin for the output and six-pin for the

stomp switch. Follow with the two three-pin vertical headers for the

potentiometers (Fig. 23, Fig. 24). Align the vertical headers as shown in the pic with their chamfered sides to the left.

We are ready to add components. |

|

|

|

Install the 100 mf. electrolytic capacitor (Fig. 25) with its positive side

in index F-2. Solder in place and trim leads on the bottom (Fig. 26). Save

those scraps of bare wire for later use in making connections!

|

|

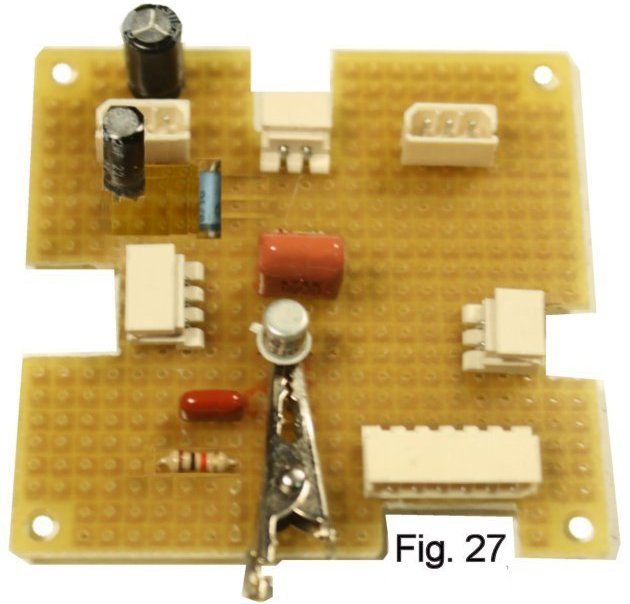

Keep adding components, working up-and down and left to right.

Capacitor C3 may span three, four or five holes depending on the make,

so form its leads accordingly. Observe

polarity for the electrolytic capacitors C4 and C5. While silicon transistors and diodes are not

as heat-sensitive as their germanium counterparts, it is a good idea to use

an alligator clip as a heat sink, putting it on each lead of the device

before soldering as in figure 27. Figure 28 shows the

board fully populated except for the LED. That goes in last, during final

assembly. When planning a board layout for manufacture as a printed circuit board,

jumpers are sometimes a way to avoid the expense of a double-sided PCB. The

two jumpers on the component side are shown as thin blue lines in the

layout drawing. They can be formed from the scraps of wire that you trimmed

from the other components, or you can use the tinned bare copper wire in the

kit. Form a jumper that spans seven holes, install in indexes M-18 through

S-18, and solder in place. The second jumper connects indices Q-14 and Q-16.

Figure 29 shows both jumpers in place. |

|

|

|

|

|

|

|

|

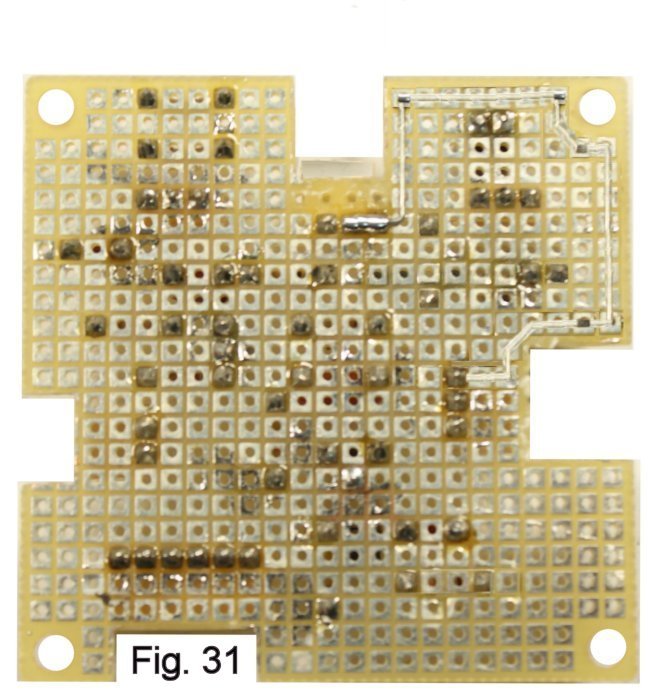

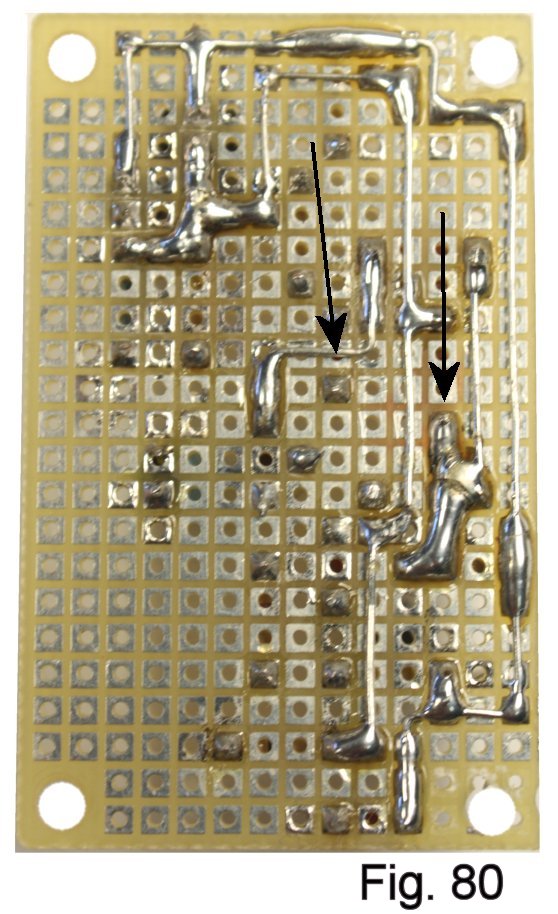

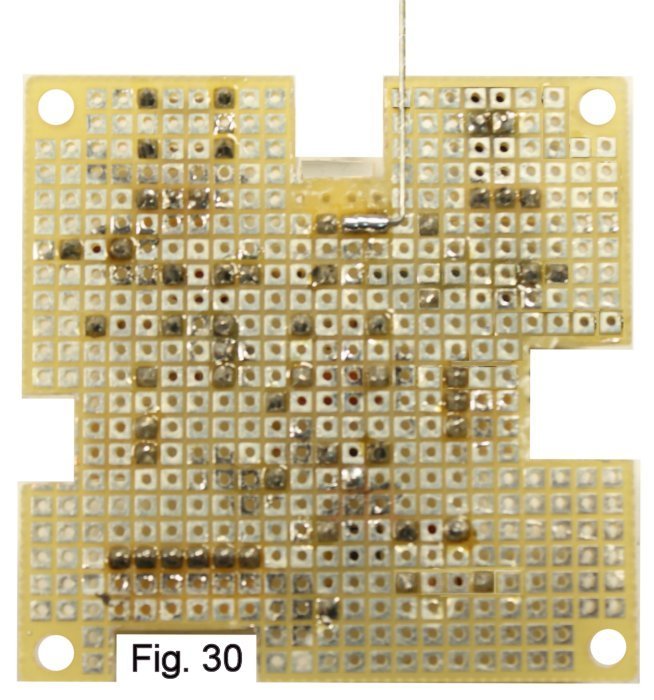

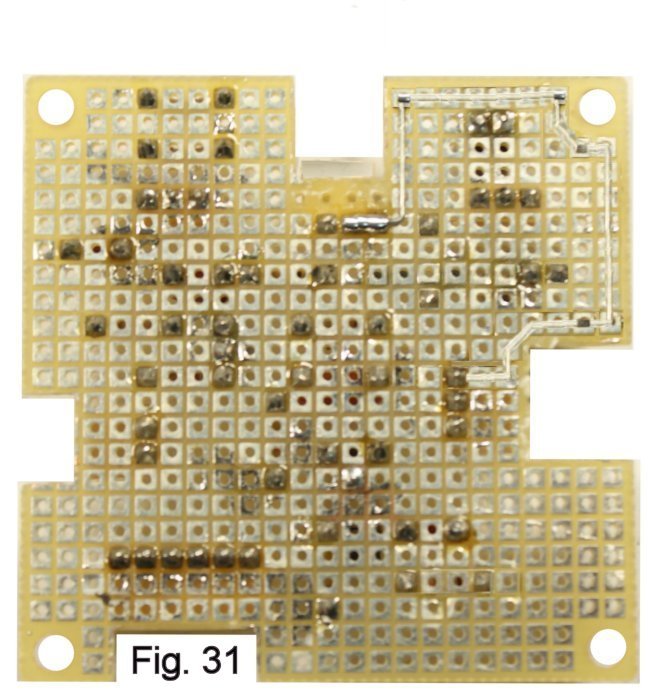

Wiring The Board Now for the plumbing! With all the components in place, we begin to make

connections between them with short lengths of bare tinned wire. First we'll

do a long one: from the negative power input to the Ring of the input jack

J2. As shown in figure 30, butt a length of bare wire up to index K-6. Use the

locking tweezers to hold it in place and solder at K-5/K-6. Now use a

chain-nose plier to put a right-angle bend in the wire. Make this as sharp

as you can, and centered in column I. "Tack" this part of the run with a

little bit of solder at index I-1, bend downward in column C and tack again at index

C-1. Bend clear of the mounting hole to get over to column A Bend downward,

right-angle bend again at A-11 and tack at B-11. 45 degree bend at D-11 and end at G-12

(Fig.31). If you want your best shot at

having the build work right off the rip and you have a multimeter, use the

continuity function every time you solder a connection to make sure that the

points you think are connected Really Are. The terminals of the connectors

Are accessible from the top of the board (Fig. 32).

. |

|

|

|

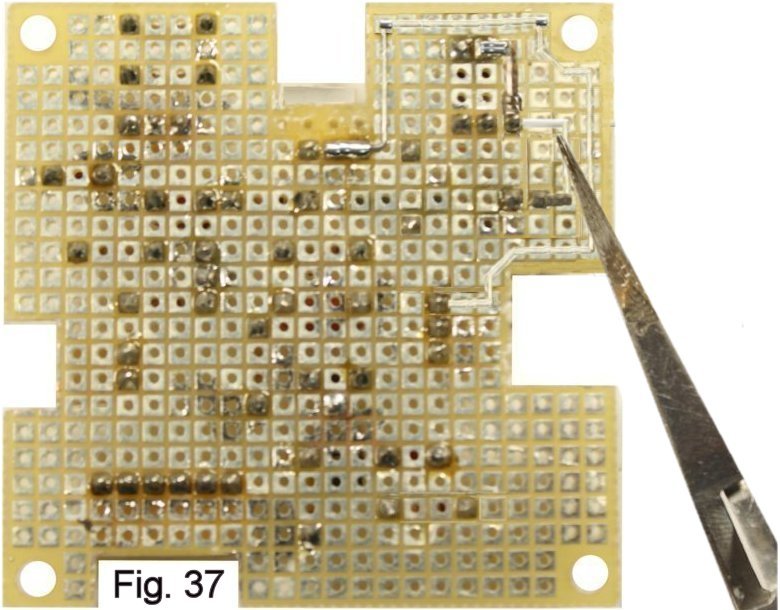

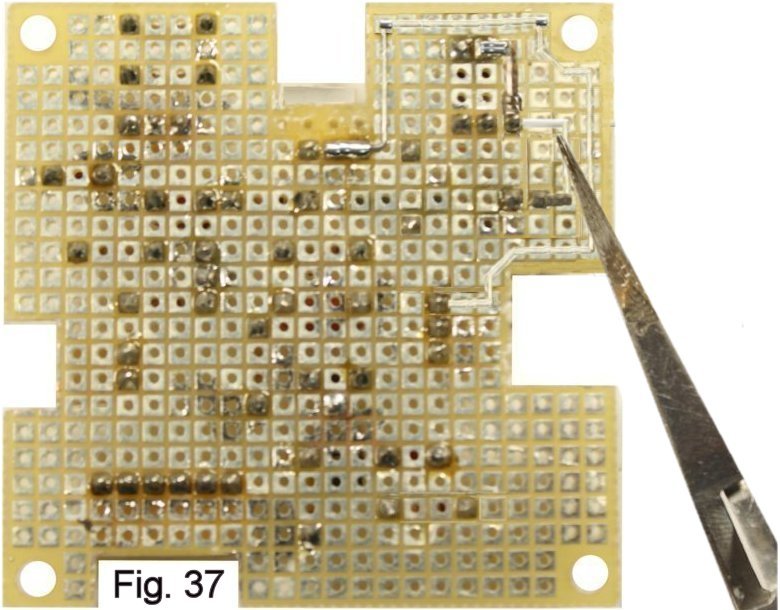

Now try the ground run that starts at the negative side of electrolytic

capacitor C1. Put a very short right-angle bend in the end of a length of

bare wire (Fig. 33). Insert the end into the hole at index D-2. Hold

this in place

with soldering tweezers (Fig. 34) and solder to join with the negative side

of the capacitor at pad E-2. Cut the wire just short of the pad for the

potentiometer connector at index D-5 and solder to join (Fig. 35). Butt the

remaining bare wire against the joint that you just made at index D-5, hold

in place with soldering tweezers and solder (Fig. 36).

|

|

Create a right-angle bend down in column 2 and another in row 8. Cut at the

negative side of electrolytic capacitor C4, index C-8. Hold the wire down

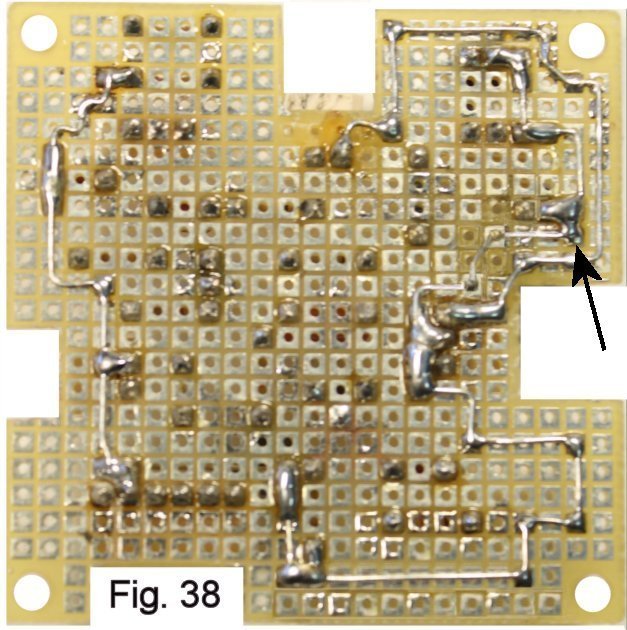

with the tweezers and solder (Fig. 37). Before continuing the run, I used the tip of my

soldering iron to remove the pads at indices G-8 and F-9. It's a way to

avoid problems where I think there might be a danger of a short between

connections. Then I set up a short right-angle bend, installed that in

index B-9 and soldered to join to B-8. This starts the rest of the ground

run as shown in Figure 38. Note that it continues after the long jumper and

ends up at R10. When finished, it is very important to test continuity all

along the run and from beginning to end (Fig. 39).

|

|

|

|

Make the connection between L-5, the positive power input, and H-6, the

positive side of diode D1. Follow with the run that connects F-2 (the

positive side of capacitor C1), H-9, (the cathode of diode D1), resistor R3

and resistor R6 (Fig. 40). I am a big fan of using the capacitance scale

found on many multimeters to test continuity where a capacitor contacts a

run on the board. Look at the layout for a second: The positive side of C1

contacts three points that are accessible on the component side, and its

negative side is grounded. So we

should see the value of the capacitor between any of those points and any

point on the ground bus, right? And so we do, as in figure 41. (The

capacitor is nominally 100 mf., but tolerance is typically 20%, so this is

in range). Used consistently, this technique will smoke out numerous joints that

are not quite connected. |

|

|

|

|

If you are with me so far, you have the basics of the technique. Here is a table of the rest of the connections in the order I

did them, with some notes where appropriate. With a highlighter, mark off

connections on the layout as you make them. |

The last step is actually installing the LED. For reasons you'll

see later, I leave this until after the board is tested and we know that the

effect works. Now, we can prepare the off-board components to connect to the

board and then do an initial test (!).

|

Assembling The Pots, Jacks and Switch If you

bought the breadboard kit and are re-using parts, unsolder the connecting

wires from the potentiometer terminals. I will presume here that you are

using my modular approach to making the connections, so find six terminated

leads and two male three-pin Molex housings (Fig. 42). Reserve the red and

black leads for power. Other than that, it's your choice for which

color goes where.

Install each lead into

its hole in the housing. The terminal has a flange on one side, and you will

feel it click into place when it is fully inserted (Fig. 43). Cut the leads

down to about 2", strip, and solder as shown to create the potentiometer

assemblies shown in figure 44. Take special care to get each pot on the

proper side and the terminal assignments correct.

In the same way that you created the connectors for the pots, install

black and red leads to set up a connector for power (Fig. 45).

|

|

Find a two-pin and a three-pin Molex plug. Assemble the connectors for input

and output, using black leads where shown in figure 46. While the other

leads can be any color, you may want to follow my example to avoid

confusion. The Bare Box #1 enclosure is tooled to be friendly to shrouded jacks like

those used in many "name" pedals. These have a chamfer (bevel) on the sleeve pin

edge, which is helpful for identifying the contacts.

Start by locating the sleeve contact of the

input jack and soldering the black center lead of the plug to this contact.

The sleeve contact is the one on the beveled edge (“chamfer”) of the jack.

For ease of assembly later, it’s best if the lead enters from the bottom of

the contact and is bent at right-angles as shown before soldering (Fig.47).

|

|

The last piece of pre-assembly before you put everything

together is creating the connector for the stomp switch and soldering those

components together.Find the six-position Molex connector and the terminated

leads for it, and assemble this as you did the others. While there is no

standard for which color goes in which position, you may want to follow what

I show in figure 48 for ease of troubleshooting.

Position the stomp switch with its terminals parallel to you

as shown in the left-hand pic. Start the wiring by connecting the two

terminals at the top left with a very short piece of bare wire, and then

solder. When making the solder terminations to the switch, take care to

route and dress the leads as shown; it’s important to being able to position

them in the case later. The right-hand pic is annotated to show which

termination goes to which contact (Fig. 49).

|

|

Initial Testing

Are you ready to test your work? Plug in pots, jacks and stomp

switch as shown in figure 50. Set both controls to their mid-points. Connect

your guitar and an amplifier and connect a battery to the power leads. If

you don't get boost, click the stomp switch. Got boost?, Tone control works?

CONGRATULATIONS!

If your build doesn't work yet, don't be too discouraged. Take a shower and grab

a bite, since we know that you haven't done either one since you started

this thing; troubleshooting requires a clear head and normal blood-sugar

level. The first rule to keep in mind is that projects like this are

all-or-nothing. If EVERYTHING is correct, the build works; if ONE thing is

wrong, it doesn't. But you have something going for you: I built from the

drawings shown here, and you can rely on them. Use them as your bible, and

you'll find out what's wrong.

To start troubleshooting, make clean copies of both the schematic and the

layout drawing. Use a highlighter to mark off connections as you check them.

Go over the off-board connections first. If those look good, you have to

verify the interconnections. Use the continuity setting of your multimeter

to make sure that you actually have a connection between every point in the

layout that is supposed to be connected, and that nothing is shorted. Found

a bug? Time to do repairs.

You can also use the low-voltage scale of your meter to sniff out

problems. With your guitar plugged in (necessary so that the battery

circuit is complete), hang the negative lead on the sleeve of the input

jack. You should see roughly the following voltages on Q1: Collector 5.48

volts, Base 2.39 volts, Emitter 1.77 volts. If any of your readings are off

these by more than 10%, you probably have a wiring error. Once everything

works, you can add the in-use LED and then proceed to the section on

finishing the enclosure. |

|

|

|

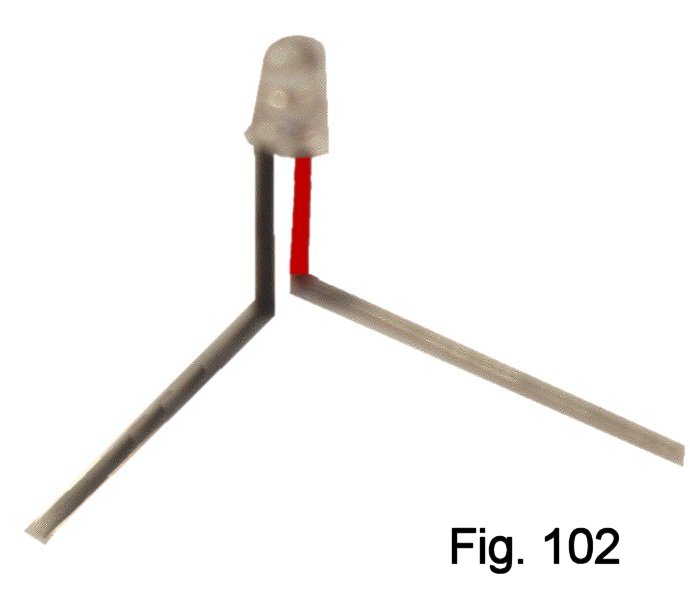

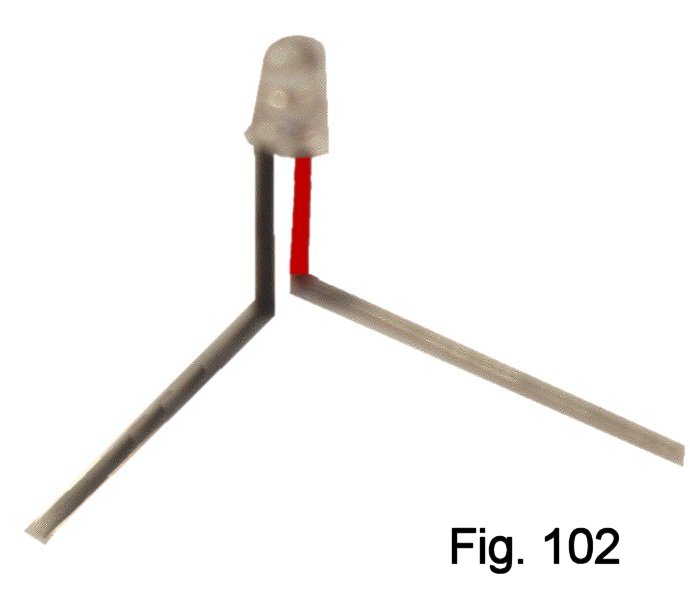

Installing The LED An LED is a diode, and so is polarized.

By convention, they are supplied with the negative lead shorter than the

positive. Insulate the leads using short pieces of spaghetti tubing, and

then bend the ends away from each other (Fig. 51).

Solder the leads to the pads on the underside of the board. Positive goes to

U-4 and negative to V-4 (Fig. 52).

Before you go further, re-assemble your test setup and make sure that the

LED works properly. If it does, the board is finished.

|

|

Finishing The Enclosure |

|

|

|

All the finishing methods I am familiar with begin with sanding to produce a

smooth finish that will be friendly to paint, powder-coating and/or decals.

I like to wet-sand starting with 220 grit Carborundum paper, and I use progressively

finer grits up to 600 to get a smooth finish.

You can get ideas and techniques for decorating and labeling from many

on-line sources as well as some of the other project articles at SBE. After

decorating, I always put a soft cloth down on my bench so that there is less

chance of ruining a paint job. Move slowly, especially when you have a tool

in your hands! |

|

|

|

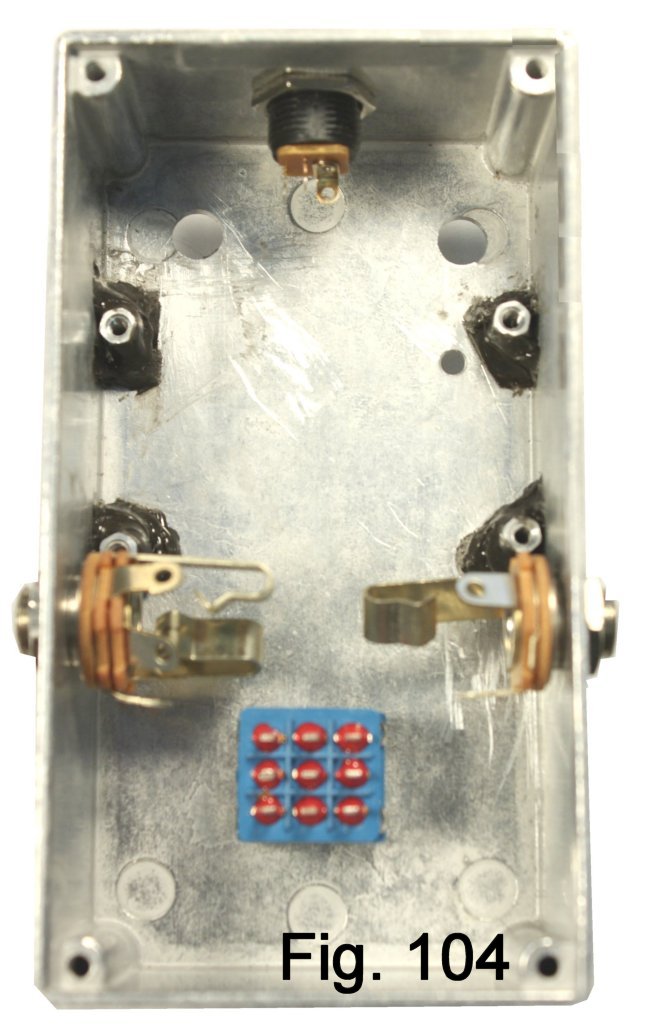

Final Assembly The next step is to wire and install the DC power jack, the

male power connector and the battery snap. Begin by slipping a ¾” length of

heat-shrink tubing onto the positive battery snap lead. Crimp the lead to

the terminal on the jack, solder, and then conform the tubing to the

connection using the side of your soldering iron.

In a similar way, attach the positive power connector lead.

The negative leads for the battery snap and the power connector go to the

ground terminal, and no insulation is needed (Fig. 53).

Before installing the assembly, thin down the shoulders of

the insulating washers so that they will allow the washers to “grab”

properly and not let the jack rotate. This can be done with sandpaper, or a

grinding stone on a Dremel tool is ideal, if you have one (Fig. 54).

The potentiometers have anti-rotation tabs that need to be cut or bent off

(Fig. 55).

|

|

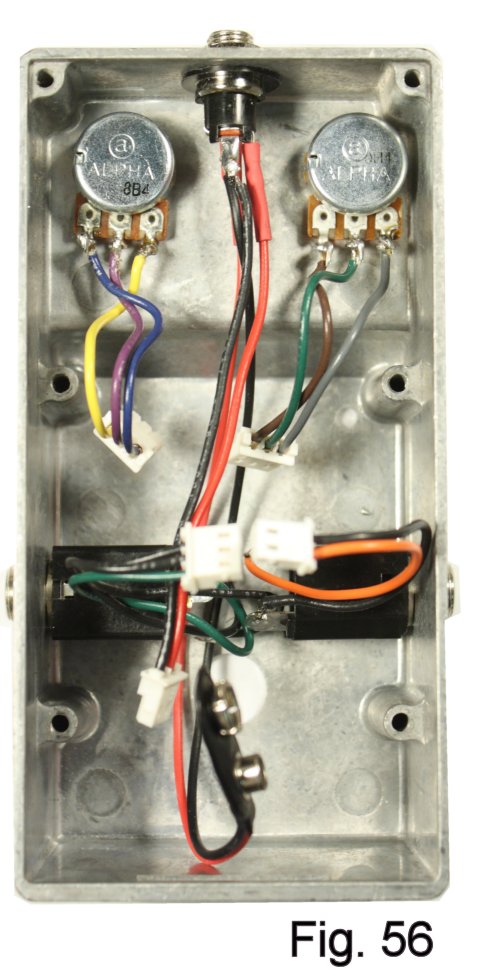

Mount the power jack assembly first, then the pots. Take care to get the

correct pot on each side. All hardware should only

be finger-tight for now. Mount the input and output jacks, dressing

the leads as shown to keep the plugs out of the way of the stomp switch

(Fig. 56).

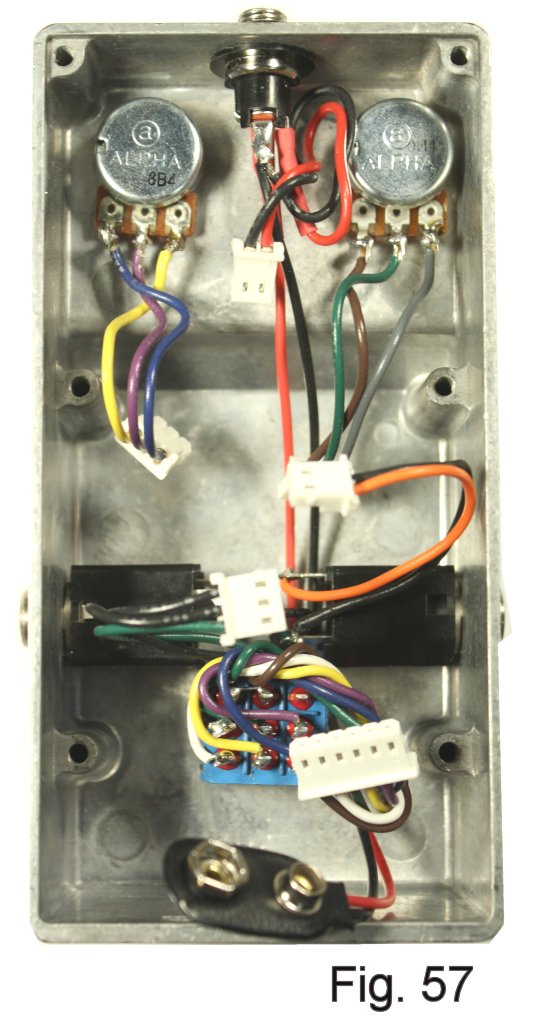

Mount the stomp switch, being sure to orient it so that the plug assembly is on the right. The battery snap leads go between the jacks

and around the stomp switch (Fig. 57). Move the plugs aside enough to ease

the board into place (Fig. 58). Plug in all of the connectors. Maneuver the LED into its mounting hole and

set

the board down on its standoffs. Install one of the round-head screws to

hold the board down temporarily. Connect your gear and a battery (Fig. 59).

|

|

Test the pedal. If something does not

work, first make sure that all of the plugs are fully inserted and that none

of the pins on the wires have worked loose. It's also possible that a

connection broke during assembly or something is shorting inside. You may

have to disassemble and go back to the troubleshooting section above.

Once everything works, finish

securing the board. The threaded studs secure the side of the board that is

next to the battery, and two of the screws that secure the lid will screw

into them. To complete the job:

- Tighten the hardware on the controls and jacks

- Secure the lid

- Stuff a small piece of foam padding over the battery

- Install the battery cover

- Install knobs

- Install rubber feet

|

|

Enjoy your new pedal! More builds employing the modular approach of the Bare

Box #1 are under development. Comments and suggestions are welcome at

smallbearelec@ix.netcom.com. |

|

|

|

A Parts List |

|

|

|

Presuming that you have all the parts in the breadboard kit, here's what's

needed for the build in the Bare Box #1: |

|

|

|

1 |

Bare Box #1 (with 6 screws and

2 studs) |

0350 |

|

1 |

DC Power Jack - Long Bushing |

0612D |

|

1 |

3PDT stomp switch |

0200 |

|

2 |

Knobs for 1/4" shaft |

0825C |

|

2 |

Molex 3-pin vertical headers |

0614S |

|

3 |

Molex 3-pin plugs |

0614U-2 |

|

2 |

Molex 2-pin plugs |

0614U-1 |

|

2 |

Molex 2-pin horizontal headers |

0614R-1 |

|

1 |

Molex 3-pin horizontal header |

0614S-1 |

|

1 |

Molex 6-pin horizontal header |

0614T-1 |

|

1 |

Molex 6-pin plug |

0614U-3 |

|

19 |

Terminated leads |

0614O |

|

1 |

Pad-per-hole perfboard |

0355 |

|

1 |

Bare tinned wire |

0509 |

A kit that includes everything on this list is available as SKU 0016C. |

|

|

|

|

|

Stuffing The Board For The Generic Build |

|

|

|

|

|

Below are the board layout and a re-cap of the parts list. You are seeing it

in "X-Ray" view; the red lines are connections that we will make with bare

wire on the bottom of the board. |

|

|

|

| R1 |

4.7 Meg |

| R2 |

1K |

| R3 |

120K |

| R4, R5, R8, R10 |

47K |

| R6 |

10K |

| R11 |

10K |

| C1 |

100 mf. |

| C2, C6, C7 |

.01 mf. |

| C3 |

.47 mf. |

| C4 |

22 mf. |

| C5 |

1 mf. |

| Q1 |

2N2222A or similar |

| D1 |

1N5818 |

|

|

Print a copy of this drawing and the schematic so that you can mark off connections with a

highlighter as you work. This is one of my time-tested methods for catching

mistakes before they cost me time and frustration. |

|

|

|

|

|

|

|

|

|

The transistor is at the center of the action, so I suggest

installing that first. I don't cover basic soldering techniques in this

article, so you may want to check a reference and do some practicing if this

is your first build. Install the transistor with its Emitter at index L-7.

Though modern silicon devices can tolerate normal soldering heat, it is good

practice to use soldering tweezers as shown as a heat sink (Fig. 61). Bend

the transistor leads flush to the board .Solder in place and trim excess

wire (Fig. 62). |

|

|

|

|

|

|

|

|

|

|

|

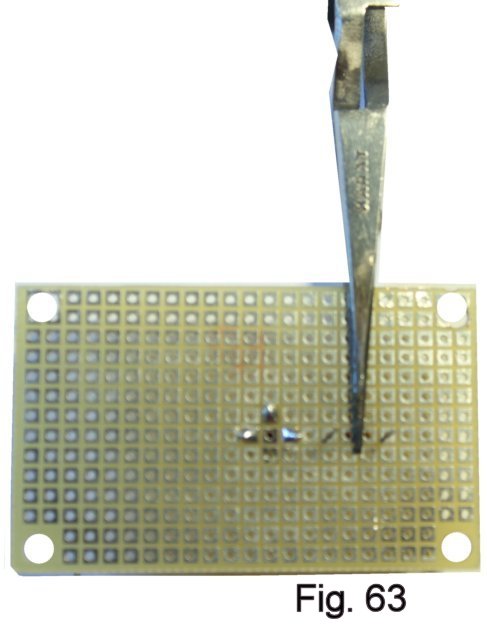

All of the resistors are formed for four holes, so the leads are simply bent

close to the body. They can be installed in any order, and heat-sinking is

not needed. An easy way to begin is with R8, which goes from index P-7 to

S-7. Hold the component in place with soldering tweezers, solder, and trim

leads (Fig. 63). Then add R4, R5, R10 and R11. Continue with the rest of the resistors on the

left side, R1, R2, R3

and R6 (Fig. 65). |

|

|

|

|

|

|

|

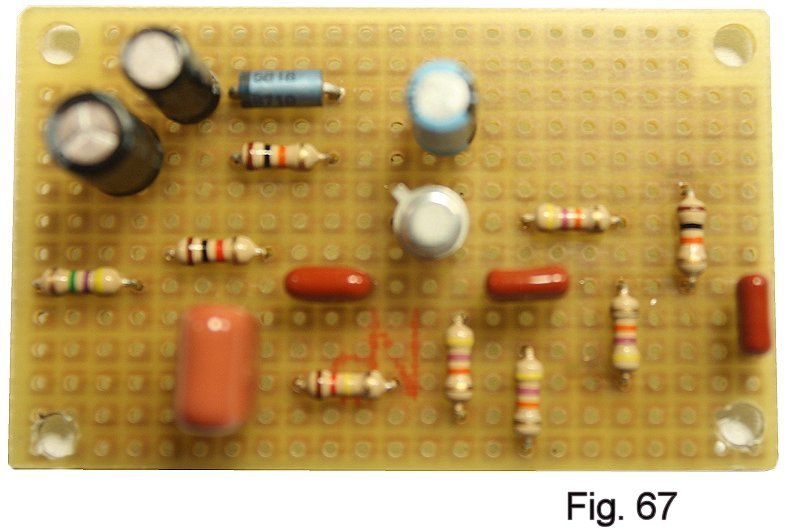

OK, capacitors. C2, C3, C6 and C7 are polyester-metal film and have no

polarity, so they can be inserted either way. C3 may span three to five

holes depending on the make (Fig. 66). Again, use soldering tweezers to hold the

component in place while soldering. When adding the electrolytic capacitors,

C1, C4 and C5, observe polarity! The same caution applies to installing

diode D1 (Fig. 67). The LED will go in last during assembly. The board is now stuffed and we can begin to wire. |

|

|

|

|

|

|

|

Let's do the ground bus first, starting at index E-3, the negative side of

capacitor C4. (I'll show you later when we do terminations how to make the

connection to E-1.) Cut a length of bare wire about 2" long. Using soldering

tweezers to hold the wire, butt it up to index E-3 as shown and solder (Fig.

68). Using the chain-nose plier, make a sharp right angle bend down column

A. Cut the wire so that it just butts against index A-9 where resistor R-1

terminates. "Tack" the run in the corner where you made the bend. Hold down

the run with

tweezers and solder to join at index A-9 (Fig. 69).

Before you continue the run, use the soldering iron to remove the

remaining pad material around the mounting holes that were added earlier.

Butt the remaining wire against index A-9 and solder to join it to the pad

(Fig. 70).

Now make two right-angle bends, one at A-12 and one at C-12. Tack the run

at C-12 and cut off at C-14 (Fig. 71). |

|

|

|

|

|

|

|

|

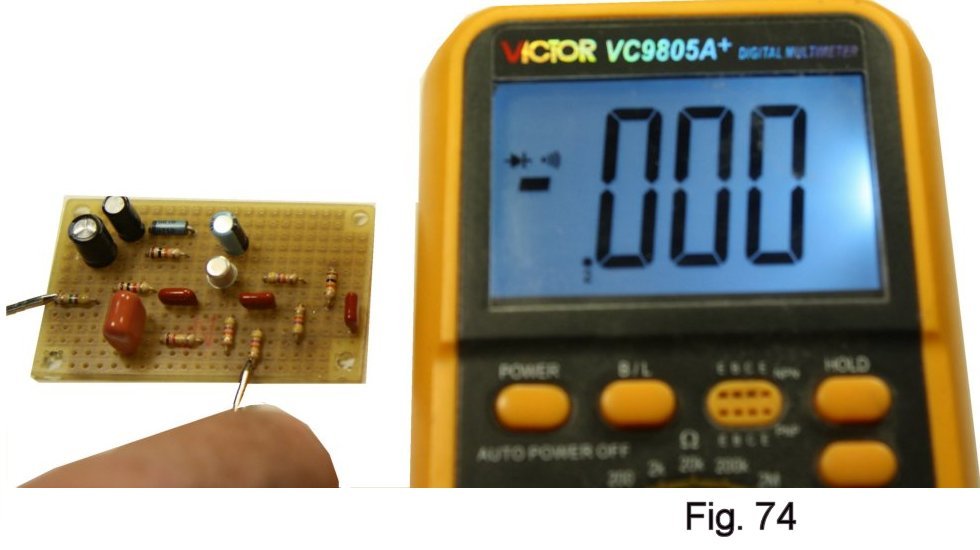

Now extend this part of the ground bus to R5 (Fig. 72) and end it at C7

(Fig. 73). A little bit

of soldering connects resistor R10 to index T-12 (also Fig. 73), and let's stop and do a test.

According to the layout, we should have a connection all the way from the

negative side of C4 to one side of C7, right? We can't easily test

continuity from C4, but we can absolutely test from R1 to R5 (Fig. 74). Got a good

connection? If not, check your soldering. If all is OK, mark off the section

you have tested on the layout, the schem, or both (Fig. 75). |

|

|

|

|

|

|

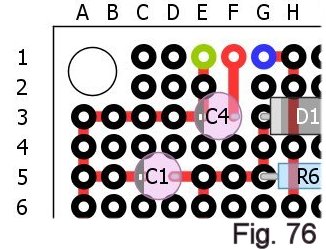

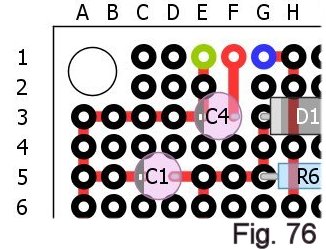

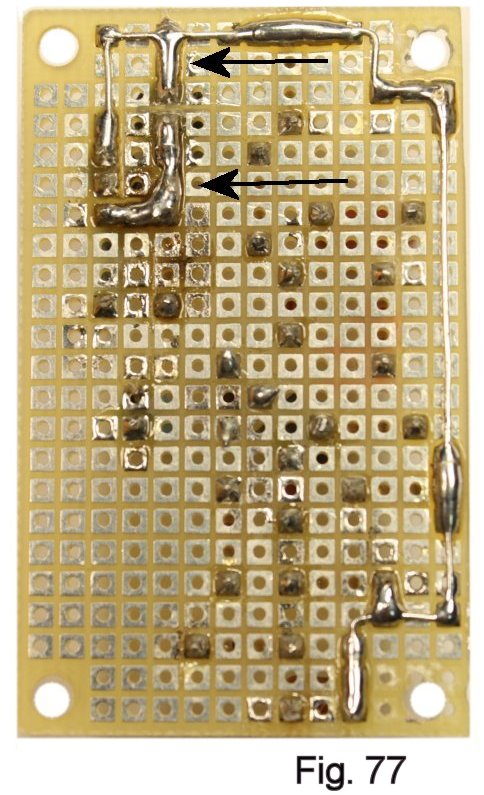

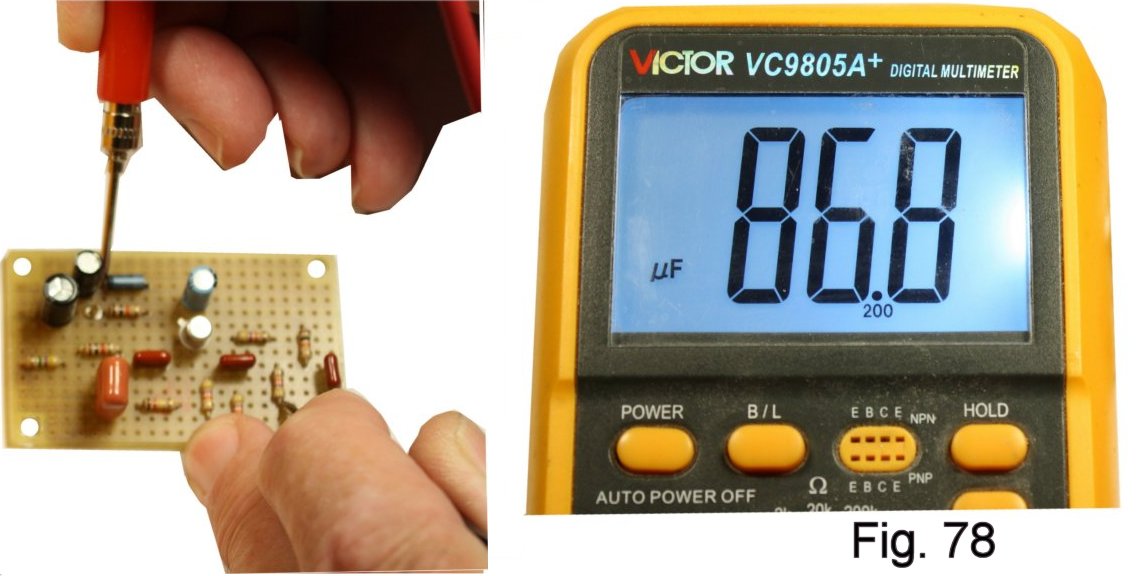

If your meter has a capacitance scale (as many do), it's possible to test

continuity through a section that contains a capacitor. Let's get the + side

of capacitor

C1 connected to diode D1 (Fig. 76) and I'll show you what I mean. You can see in the

pic where I have made the connection between the + side of C1, R6 and the

negative side of the diode. I have also made the connection between the negative

side of C1 and the ground bus. So it would make sense that if I measure

capacitance from the negative (bar) side of D1 to any point on the ground

bus, I should see about 100 mf. I see 86.8 here, and that's within the normal 20%

tolerance for an electrolytic, so I'm good. Use this technique wherever

convenient to help ensure correct wiring! |

|

|

|

|

|

|

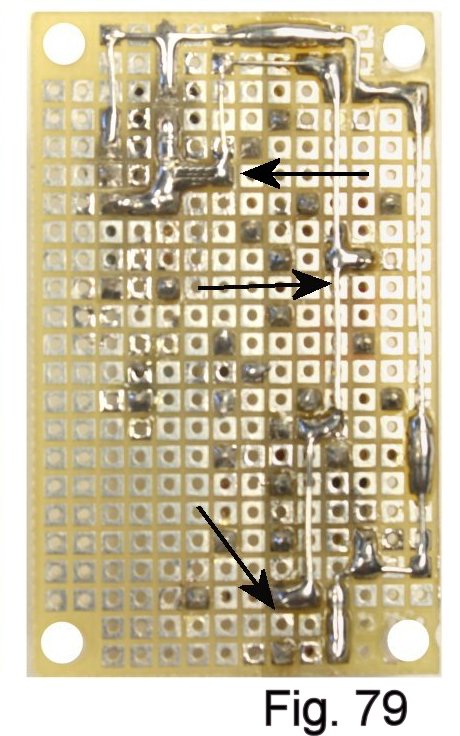

Next, lay down the positive supply bus starting at index E-5. Tack it at B-7

and B-11 for mechanical stability. Then pick up

one side of resistor R3 and end on one side of resistor R11 at index U-9.

Join one side of resistor R5 to one side of resistor R3 and pick up one side

of resistor R4. Then do a run to one side of capacitor C3. The opposite side

of C3 terminates at the Emitter of the transistor, and that's a good point

from which to do the capacitance/continuity test if you can. |

|

|

|

|

|

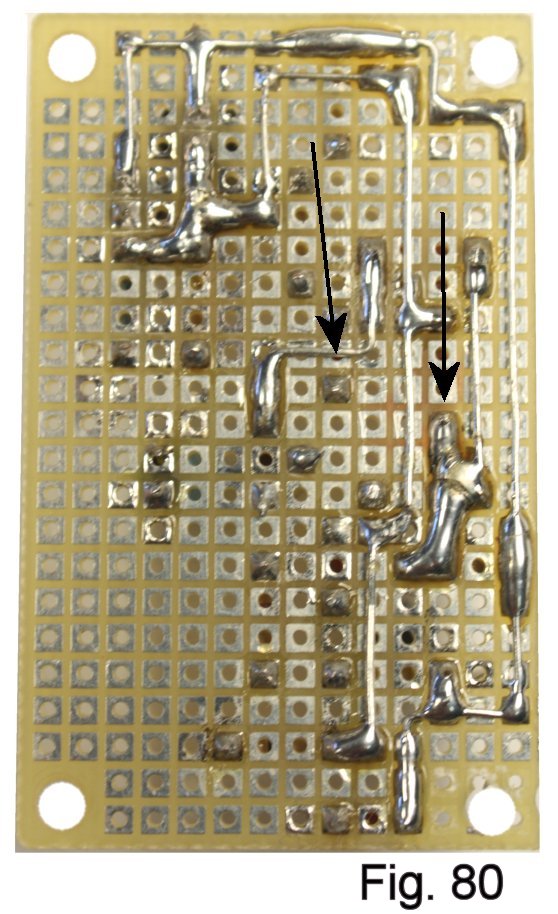

Here is a list of the remaining connections in the order in which I did them

with some notes where I thought they would be helpful: |

|

|

- R1 to R2. Avoid getting solder on pad D-8 when making this connection,

because we will add a termination there later.

- R2 to C2

- Index H-1 to index J-7. Leave index G-7 clear for now. After we do the

terminations later, you can test continuity from the Emitter of Q1 to this

point.

- Base of Q1, one side of capacitor C2 and one side of resistor R4

- Collector of Q1 to positive side of C5 and join to R6

- Negative side of C5 to capacitor C6 and pick up one side of resistor

R8

- Leave index P-1 open for a termination. Start a run from just below

index P-1 to one side of capacitor C6 and one side of resistor R10

- Leave index R-1 open for a termination. Start a run from just below

index R-1 to one side of resistor R8 and one side of capacitor C7

- Leave index S-3 open to add the + side of the LED later. Start a run

from just below index S-3 to one side of resistor R11

- Leave index T-3 open to add the - side of the LED later. Start a run

from just to the right of index T-3 to just short of index W-4

The board is wired, and we can prepare to connect to off-board

components. |

|

|

|

Terminations |

|

|

|

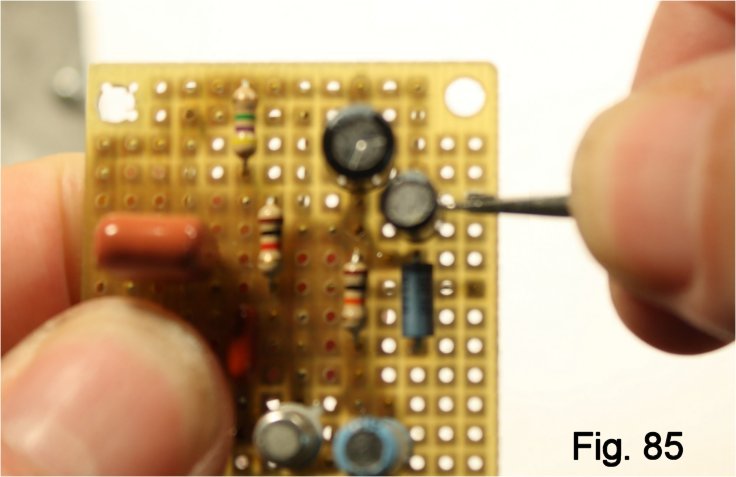

Too many DIY builds will have you insert leads in the holes (Fig. 82), connect to

pots, jacks and switches and then stuff the board in the

enclosure. I find these methods tacky and won't teach that way. One "right"

way to terminate to an off-board component is to insert a push-in terminal

(I call these "flea clips") into the appropriate hole and solder on the

underside of of the board. Then you can mount the board on standoffs and

wire to the terminals. Start with the hole at index E-1. Enlarge the hole

slightly by "working" it with an awl or straight pick (Fig. 83). Squeeze the bottom of

the terminal slightly with the chain-nose plier (Fig. 84), insert in the hole, and

push down in the top slot--firmly and steadily--with the side of a small

screwdriver to seat the terminal (Fig. 85). |

|

|

|

|

|

|

In many cases, you can immediately solder the terminal in place on the

bottom. I wanted to bridge the one-pad gap to index E-3, so I made use of

the fact that the terminal has a hole in the bottom for inserting wire. I

re-opened the flange with a pick to enlarge the hole, slipped a bit of wire

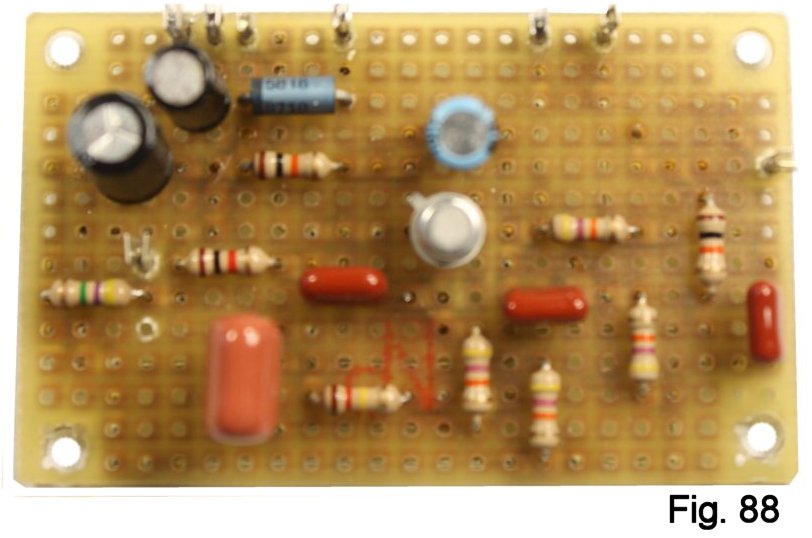

in (Fig. 86), soldered and trimmed (Fig. 87). Done. The remaining terminals are installed at

indexes F-1, G-1, J-1, P-1, R-1, D-8 and W-4 (Fig. 88). The board is finished, and the

next step is to prepare the enclosure.

|

|

|

|

|

|

|

If you bought a kit, the enclosure is already drilled. If not, and you are

rolling-your-own in a 125-B box, you can download from

here a page of

drilling templates. Never used these? Here is a quick review of my methods:

- With a good, sharp scissor, cut out the top template.

- Attach a couple of pieces of double-sided clear or masking tape to the

box, and carefully center the template to the cover.

- In the same way, attach the templates for the sides, being careful to

get the holes for the jacks in the correct locations to the right and left

of the switch.

- Use a scribe or scratch-awl to put a small dent at the center mark of

the hole for the stomp switch (Fig. 89).

- If you use standard twist drills, bore a 1/8" pilot hole, enlarge it with a ¼" drill, and then use a tapered reamer to slowly bring the hole to its final size.

- Follow the same procedure for the other three holes on the top, and then the holes on the sides.

- De-burr all of the holes with a small, round file. Remove all of the

templates and tape, and you should have the result shown (Fig. 90).

Note: Many people like using a step drill (the common trade name is Unibit) rather than separate drills, because it does a quick, clean job of boring any size hole from 1/8" to 1/2"

(Fig. 91). |

|

|

|

|

|

|

|

Before installing standoffs for mounting the board, do any painting or

decorating that you want to. There are so many choices and methods for how

to do this that they really need a separate treatment. You can find lots of

discussion and useful infomation by searching past threads on the Forum.

Once the enclosure is decorated, you want to keep it from accidentally being

dinged while you work. Put a soft cloth down on your work surface to protect

the face, and Move Slowly, especially when you have a tool in your hands

(long experience!). |

|

|

|

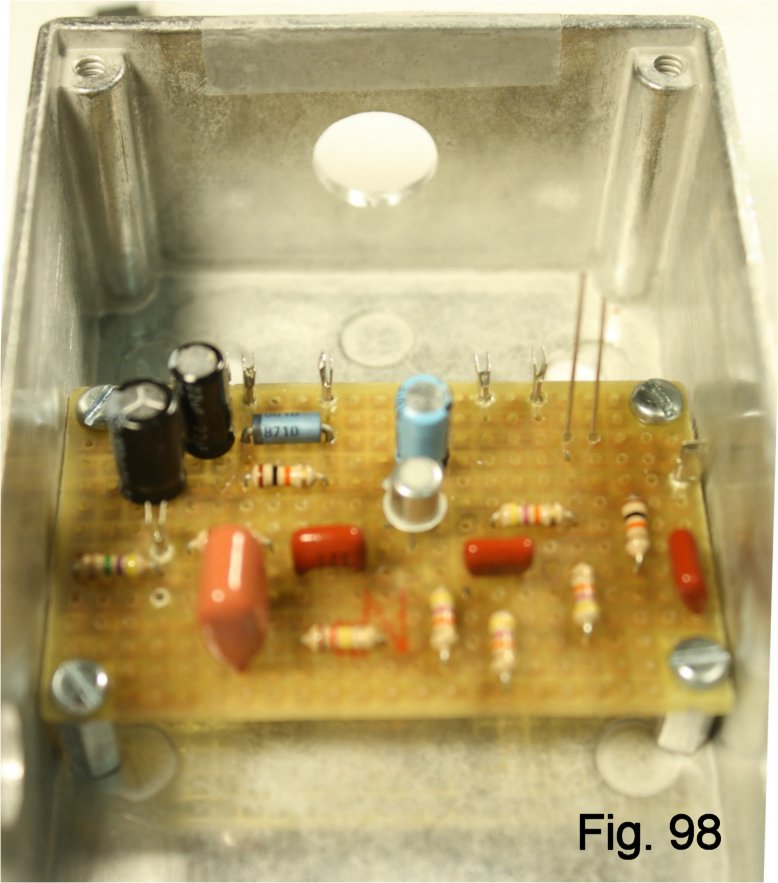

I have noted that I insist on using standoffs of some kind to anchor the

board rather than supporting it on a few wires and stuffing the case with

styrofoam. There are numerous metal and/or plastic hardware items that can

be used to secure a board, and the choice depends on a mixture of mechanical

needs and cost. Plastic standoffs (Fig. 92) won't fly here because the

board butts against the walls of the box. Better, in this case, to use epoxy

cement to attach aluminum studs (Fig. 93) to the case. Done right, this results in a

gig-worthy and reliable build. The ones shown are hex-shape, 3/8" long and

tapped for a 4-40 screw, Keystone #1892. The kit includes four of them and

four screws. First job is to mark the areas in the enclosure that need to

be prepped. Set the LED in place temporarily at indexes S-3 and T-3, and

lower the board into place (Fig. 94). The LED should be exactly vertical its holes.

Now mark the locations of the mounting holes with a pick or scribe (Fig. 95). This

indicates the areas where the surface of the box will need to be cleaned. |

|

|

|

|

|

|

With coarse sandpaper (80 or 100 grit), roughen the marked areas on the

floor and on the walls above the marks. Then scrub thoroughly with a Q-tip

wetted with acetone. Screw the studs to the board (finger-tight only) and

prep them the same way that you did the box--roughen and clean up with

acetone. Again place the LED temporarily and set the board in place. Take

care not to touch any of the surfaces you prepped. |

|

|

|

|

|

|

Mix a small volume of quick-setting epoxy cement (I like J-B Weld). Apply a

small amount of the epoxy to the accessible areas at the base and sides of

the studs. WAIT a few hours until the epoxy has cured thoroughly and then

remove the screws. Take out the screws, remove the board and beef up

the epoxy all around each stud, taking care to avoid the LED hole.. NB: If you don't like having to go through

all of this (and I really don't, even though I know it's necessary), check

out the Bare Box #1; the studs are cast into the side walls and all of the gluing

is eliminated. Prepare the LED for mounting by cutting two 3/8"-long

pieces of vinyl tubing (saved scraps from insulated wire work for this) and

sliding on to the leads. The shorter lead is negative. Using the chain-nose

plier, bend the leads at right-angles to each other. Cut down the ends and

solder in place on the bottom of the board, being careful to observe

polarity. When you assemble now, the LED will drop into its hole. |

|

|

|

|

|

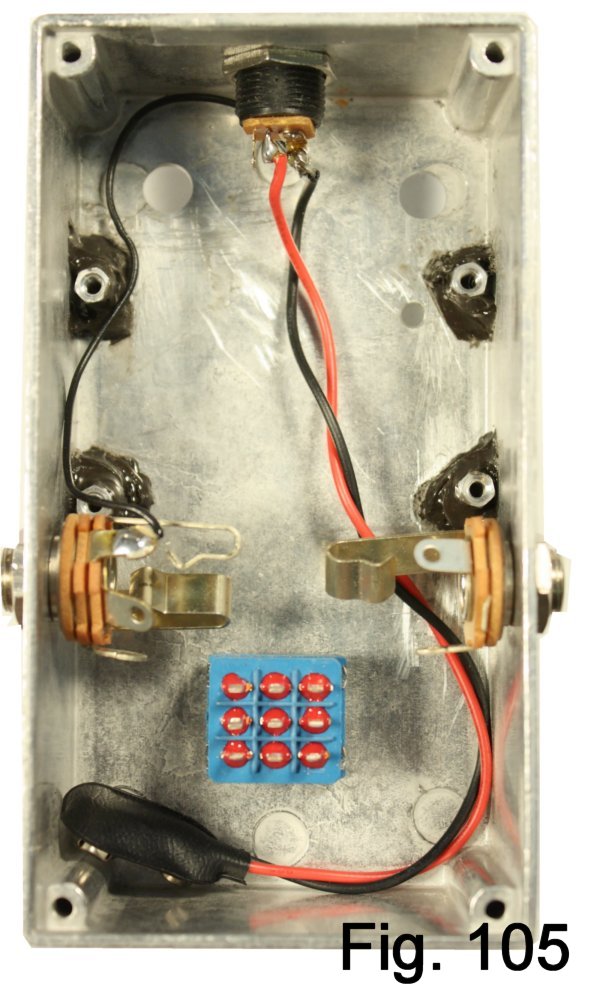

I know that you were wondering if we would ever get here...We are ready to wire!

Install the stomp switch and jacks, orienting all as shown with hardware on

finger-tight.

- Wire from the Ring contact of the stereo jack to the center-pin

contact of the power jack. The center-pin also gets the negative lead of

the battery snap. The positive battery snap lead goes to the switched

contact. Refer to figure 4 if you need to.

- Create a ground run that connects the sleeve contacts of the jacks.

The sleeve of the stereo jack gets a connection that will terminate on the

board later. The sleeve of the mono jack gets a connection that will

terminate on the stomp switch later.

- The board can be installed.

- Wire the stomp switch: Solder a jumper between contact #1 and contact

#4. Use different colors of wire to make tracing easier. Rout the wire

from contact #6 under the board. This will terminate later on the tone

pot.

|

|

|

|

|

|

|

Solder short different-colored leads to the terminals of the (5K) boost

potentiometer and mount the control with hardware finger-tight. Take care to

solder each terminal to its correct termination on the board. The ground

connection from the jacks and the CCW terminal of the potentiometer both

terminate at index E-1. Install the tone potentiometer in the same way.

The lead from the stomp switch goes to the center terminal. Make the short

connection to the power jack from the + power input of the board. |

|

|

|

|

|

|

The pedal is ready to test. Connect a battery and your gear and see if the

controls work. I built exactly what you see here, so you should have action

if everything is as posted. |

|

To complete the job:

- Tighten the hardware on the controls and jacks

- Secure the lid

- Stuff a small piece of foam padding over the battery

- Install the battery cover

- Install knobs

- Install rubber feet

|

|

|

|

Troubleshooting |

|

|

|

The first rule to keep in mind is that projects like this are

all-or-nothing. If EVERYTHING is correct, the build works; if ONE thing is

wrong, it doesn't. But you have something going for you: I built from the

drawings shown here, and you can rely on them. Use them as your bible, and

you'll find out what's wrong.

To start troubleshooting, make clean copies of both the schematic and the

layout drawing. Use a highlighter to mark off connections as you check them.

Go over the off-board connections first and verify that the connections to

power, jacks and switch are correct. If those look good, you have to

verify the interconnections. Very Carefully, disassemble the pedal and lift

the board and controls out of the enclosure. Use the continuity setting of your multimeter

to make sure that you actually have a connection between every point in the

layout that is supposed to be connected, and that nothing is shorted. Found

a bug? Time to do repairs.

You can also use the low-voltage scale of your meter to sniff out

problems. With your guitar plugged in (necessary so that the battery

circuit is complete), hang the negative lead on the sleeve of the input

jack. You should see roughly the following voltages on Q1: Collector 5.48

volts, Base 2.39 volts, Emitter 1.77 volts. If any of your readings are off

these by more than 10%, you probably have a wiring error. |

|

|

|

Enjoy your new pedal! More builds employing this basic two-knob platform are under development. Comments and suggestions are welcome at

smallbearelec@ix.netcom.com. |

|

|

|

A Parts List |

|

|

|

Presuming that you have all the parts in the breadboard kit, here's what's

needed for the generic build: |

|

|

|

1 |

Enclosure 125-B |

0306B |

|

1 |

3PDT stomp switch |

0200 |

|

2 |

Knobs for 1/4" shaft |

0825C |

|

4 |

Studs |

8009 |

|

4 |

4-40 Screw x 1/4" |

8003 |

|

1 |

Pad-per-hole perfboard |

0355 |

|

8 |

Push-in Terminals |

0400C |

|

1 |

Bare tinned wire |

0509 |

|

1 |

Hookup Wire |

|

A kit that includes everything on this list is available as SKU 0016D. |

\

\